Address:7th Floor, Gaofeng Building, Dalang Street, Longhua District, Shenzhen

Website:www.longstartech.com.cn

TEL:0755-2556 9680

FAX:0755-2556 6650

Mobile:13316929948(同V)

Email:James@longstartech.com.cn

Contact Person :James

If the ultraviolet rays from the light source were consistent everywhere, it would be much easier to measure, but that's not the case.

Uv intensity varies with distance. Theoretically, if a point source emits light uniformly in all directions through a nonabsorbable medium, the irradiance is inversely proportional to the square of the distance. This is just a theory, because in reality UVLED is neither a standard point light nor propagating in a nonabsorbent medium.

Traditional UV lamps are not always single-point sources. As shown in the opening image, UV light from the lamp strikes the detector of the radiometer from multiple angles. The reading above the radiometer is different from the oblique reading. This phenomenon is called cosine bias. In order to correctly measure light from different angles, the instrument must correct the effect of the Angle between the detector and the light source.

The angular cosine correction is achieved by modifying the response of the detector and optical elements such as diffusers. Regardless of the incident Angle, the perfect combination of detector and diffuser has unit Angle cosine correction. For existing instruments, optical elements are designed to implement or replicate the cosine response in the instrument.

The second complication of measuring presence is that these tiny leds don't glow evenly in all directions. The optical properties of current LED light sources make it more challenging to decide where best to measure their UV output.

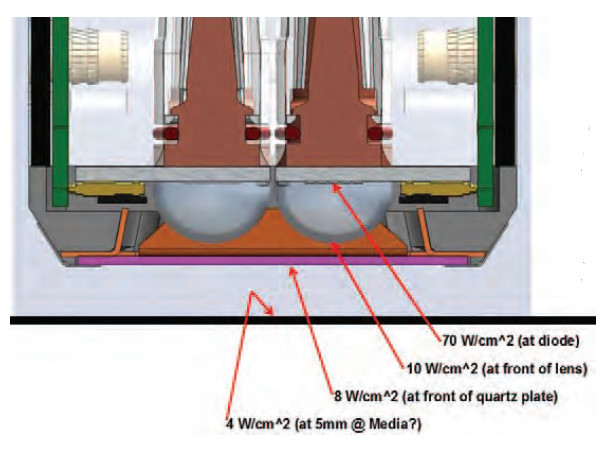

More recently, LED manufacturers have begun developing optical components that can change their array output again, sometimes targeting higher irradiance metrics. Different optical components developed by different manufacturers lead to inconsistent measurement of UVLED irradiance standards, not to mention industry standards. As shown in the figure above, the measurements differ from one another, even within a few millimeters, and the results can vary widely. The energy can be as high as 70W/cm squared at the semiconductor luminescence point, and it will weaken to 10W/cm squared at the hemispheric lens surface. The light outlet window of the irradiation head will become 8W/cm squared, and it will be 5mm away from the light outlet window, and the energy will be halved. It can be seen that the difference of the measured position is great.

More recently, LED manufacturers have begun developing optical components that can change their array output again, sometimes targeting higher irradiance metrics. Different optical components developed by different manufacturers lead to inconsistent measurement of UVLED irradiance standards, not to mention industry standards. As shown in the figure above, the measurements differ from one another, even within a few millimeters, and the results can vary widely. The energy can be as high as 70W/cm squared at the semiconductor luminescence point, and it will weaken to 10W/cm squared at the hemispheric lens surface. The light outlet window of the irradiation head will become 8W/cm squared, and it will be 5mm away from the light outlet window, and the energy will be halved. It can be seen that the difference of the measured position is great.